Diesel engines: the essentials

Geplaatst door Aaron Cremona op

A lot of the drivers who have already opted for a diesel-fueled vehicle are well aware of their advantages and peculiarities. However, those who are only starting to deal with this kind of engines may have lots of questions. We’ll try dealing with those in our article.

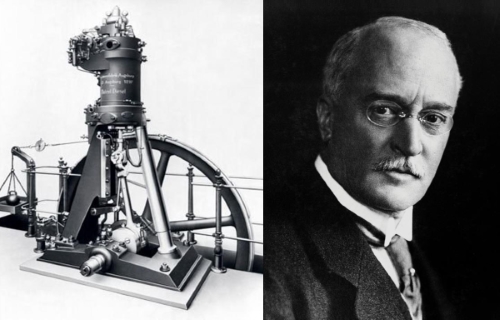

Diesel engine: the history

The diesel powertrain was first conceived in 1824, when the French physicist and mathematician Sadi Carnot theorised that for a heat machine to be more efficient, the working medium inside it should be heated to its flash point by rapid compression. This principle was later used as foundation for the first diesel engine.

Over the years, various scientists would work on diesel engine design, among whom were Herbert Akroyd-Stuart and Gustav Trinkler. However, it was not until 1887 that Rudolf Diesel managed to construct the first practically applicable and efficient prototype.

The inventor originally believed that the best fuel for his engine would be coal dust but due to its abrasive properties and complications arising from supplying such fuel to cylinders he had to give up on the idea. On the other hand, Diesel’s invention worked well on vegetable oil and light-end oil products.

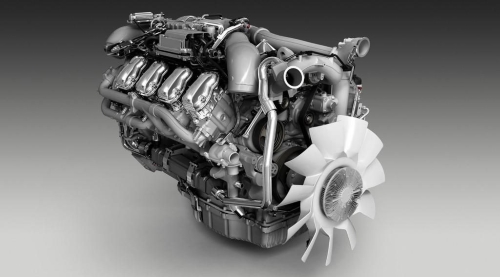

Diesel engines have been continuously improved and updated ever since. A lot of modern passenger vehicles and most commercial vehicles are equipped with these powerful, reliable and efficient power units.

Working principle

Passenger cars today mostly come with 4-stroke engines. Their work cycle includes 4 strokes/stages/steps:

- Intake, corresponding to the crankshaft turning from 0 до 180°. At this stage, air enters the cylinder via an open valve.

- Compression: During this stroke the crankshaft travels from 180 to 360°. The piston causes the air already in the chamber to be compressed 16–25 times and its temperature to rise to 700–900 °C.

- Combustion: At this stage, corresponding to the crankshaft travelling 360–540°, fuel is injected and ignites. The substances produced as a result make the piston go down.

- Exhaust: As the crankshaft travels 540–720° relative to its starting position, the piston moves upwards, and burnt gases are exhausted.

In diesel engines, fuel is introduced via an injection pump. There are several types of fuel pumps used in modern vehicles:

- In-Line. They contain plunger pairs equaling engine cylinders in number. The camshaft connected to the crankshaft causes the plunger to move, which alternately opens and closes intake openings. As a result, pressure is created for opening the injection valve, and the fuel enters the corresponding injector. These pumps are highly reliable, but are mostly installed on cargo vehicles: manufacturers stopped equipping passenger vehicles with in-line pumps in 2000.

- Distributive. Their construction features one or two plungers which make rotating and reciprocating movements, distributing fuel between all cylinders. This ensures a more even fuel distribution but wears out the components. For this reason, distributive pumps are mostly installed in passenger cars.

- High pressure pumps. These are used in Common Rail fuel supply systems and serve to pump fuel into the fuel rail where high pressure is maintained at all times regardless of the engine mode. Using this system allows to increase engine torque by 25% at low rpm and reduce fuel consumption by 20%.

- Unit injectors. A unit injector with compression and injection functions corresponds to each cylinder. Using this system allows to increase fuel efficiency of the vehicle and reduce exhaust toxicity since the injection process itself is done in 3 stages. Pre-injection ensures smooth combustion while post-injection facilitates soot filter regeneration.

5 key advantages of diesel engines

- They consume significantly less – 30% less, on average - fuel as compared to petrol engines. This is due to the high pressure inside сombustion chambers, engine design, its working principles, and a number of other factors. Besides, in most countries, diesel fuel costs less than petrol.

- In diesel engines, fuel burns away continuously right after it is introduced inside, ensuring a high torque on low revolutions. This improves the vehicle’s traction, dynamic and handling performance.

- They have a high efficiency at times reaching up to 50%.

- Thanks to the glowplugs and heated injectors, diesel engines start smoothly regardless of ambient temperature.

- They last almost twice as long as petrol engines.

Diesel engines: 9 rules of operation from AZ European experts

Follow these simple rules to avoid frequent repairs of the engine and fuel system:

- Change the fuel filter and the fuel-water separator on time. Diesel components are highly sensitive to mechanical particles and water. Because of their intricate construction, injectors and pump components get clogged up easily, while the sulfur from the fuel mixes with water and converts into sulfuric acid that has a detrimental effect on engine components.

- Make sure you fill up on quality fuel. High sulfur content in low-quality fuels greatly reduces the service life and efficiency of engine oil, and can cause failure of the soot filter.

- Avoid high rpm driving: it creates extra strain on the engine.

- Always make sure to match your fuel with the ambient temperature. Diesel fuel contains paraffin that freezes at low temperatures. Therefore, in winter it is recommended to use winter (for temperatures between -25 °C and 0 °C) or arctic fuel that retains its viscosity at temperatures between -35°C and 0°C. Service stations usually indicate the temperature range of the fuel they sell.

- Thoroughly select additives for diesel fuel, too. If you drive in areas with a harsh climate, anti-gel formulas will be a good match for your car. There also exist additives allowing to boost engine torque and efficiency by increasing efficiency of the air-fuel mixture, as well as cleaning agents for the engine and fuel lines.

- Alternate urban driving with countryside trips to let the engine run at 2,500 rpm from time to time. In this driving mode, the soot and carbon deposits burn away, reducing the risk of injectors getting coked up, piston ring sticking, and the catalytic converter failing.

- A turbocharged engine should not be shut down right after bringing a car to a stop; let it idle for 2-5 minutes so the turbine can cool down.

- Always purchase the engine oil recommended by your car’s manufacturer and never mix lubricants of differing viscosities.

- Start off smoothly to avoid damaging bushings inside the turbine.

Conclusion

Modern diesel engines are economical and powerful. Despite the stereotypes, they are eco-friendly and noiseless. Cars equipped with diesel engines would be a great fit for smooth countryside trips; they are convenient for large groups, families, and they won’t fail even with frequent use. They are very reliable off-road, hence their popularity with fishing, hunting, and outdoors enthusiasts. However, if you have always fancied a sports car, or you tend to accelerate and brake abruptly when driving, a diesel-powered car wouldn’t suit you: aggressive driving style will put too much strain on the engine.

Repairing a diesel engine is costly. However, following the tips listed above means the necessity to repair it won’t arise often.